- Whitacre Balancing Tank CFD

Impounding Reservoir

Whitacre Balancing Tank CFD

Client: Severn Trent WaterScale: N/A

Introduction

Whiteacre Water Treatment Works is a Victorian era treatment plant in Blythe End, Birmingham. The works output is rated at 44Ml/day, which equates to 510 l/s. Raw water is drawn from the river Blythe and Bourne via a number of reservoirs and passes through several treatment processes before entering a balancing tank and finally to a high lift pump station, which in turn delivers flow to service reservoirs prior to entering supply.

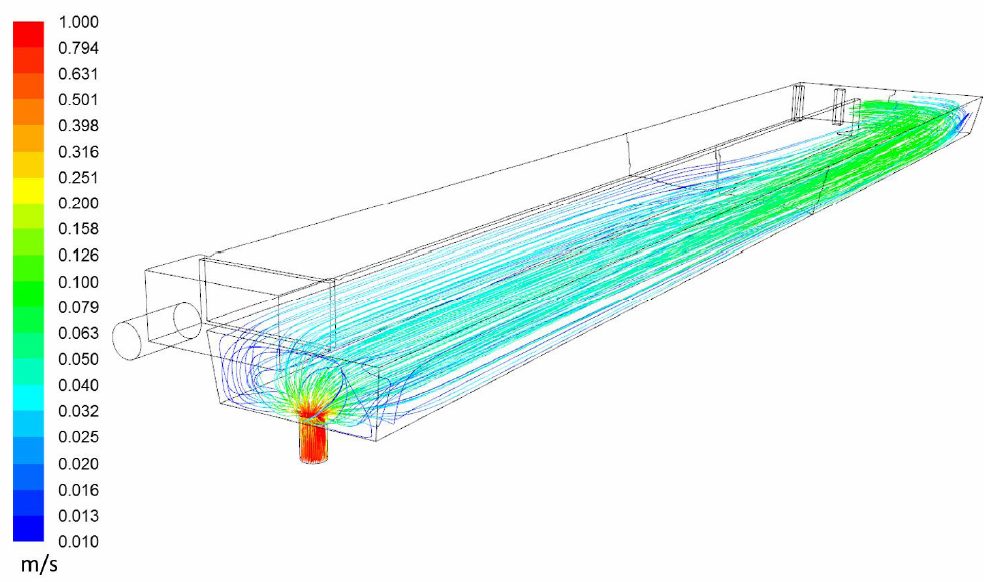

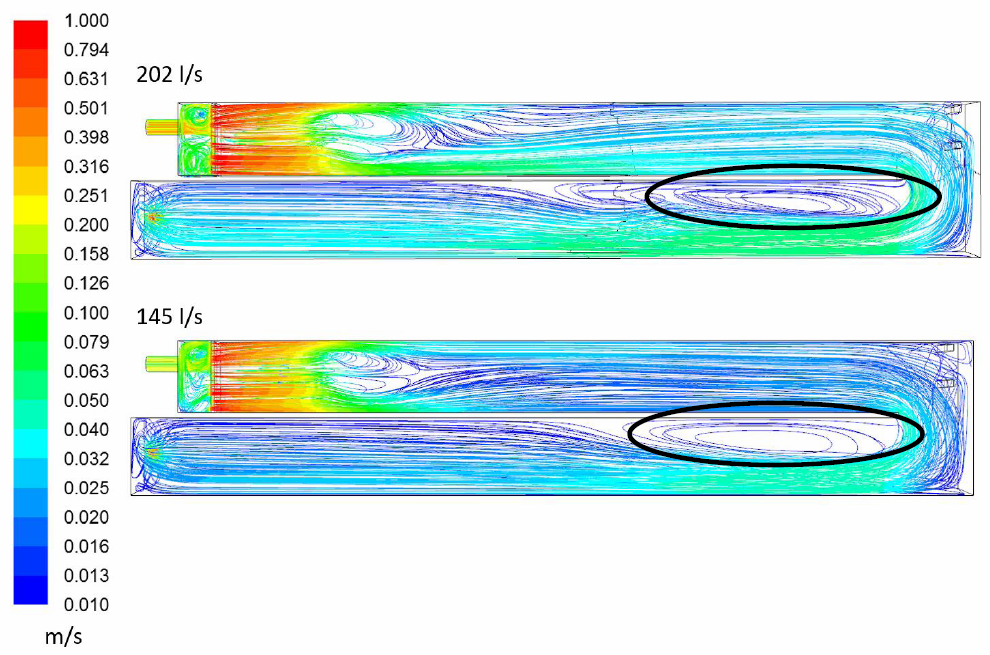

The existing balancing tank provides a working volume of 1400 m3 for the downstream high lift pumping station. Several areas of stagnation and the formation of a surface film and ‘slime’ deposits have been noted on site, resulting in concern over a potential deterioration in water quality. The origin of the film and slime has not been identified, however, it is suspected that short circuiting of flow passing through the tank is resulting in dead zones, which have allowed the formation of the aforementioned film and slime.

Initial assessment and development

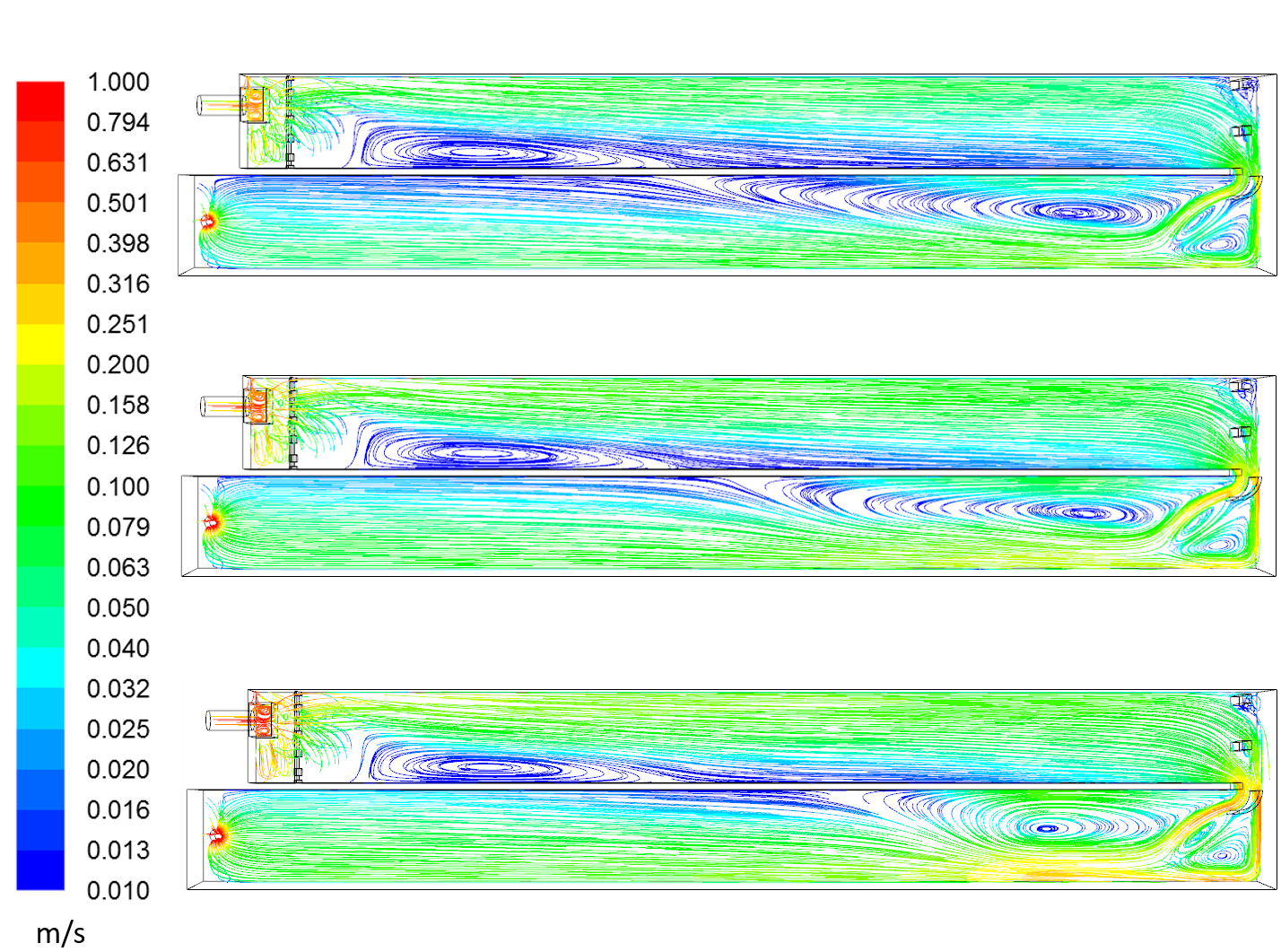

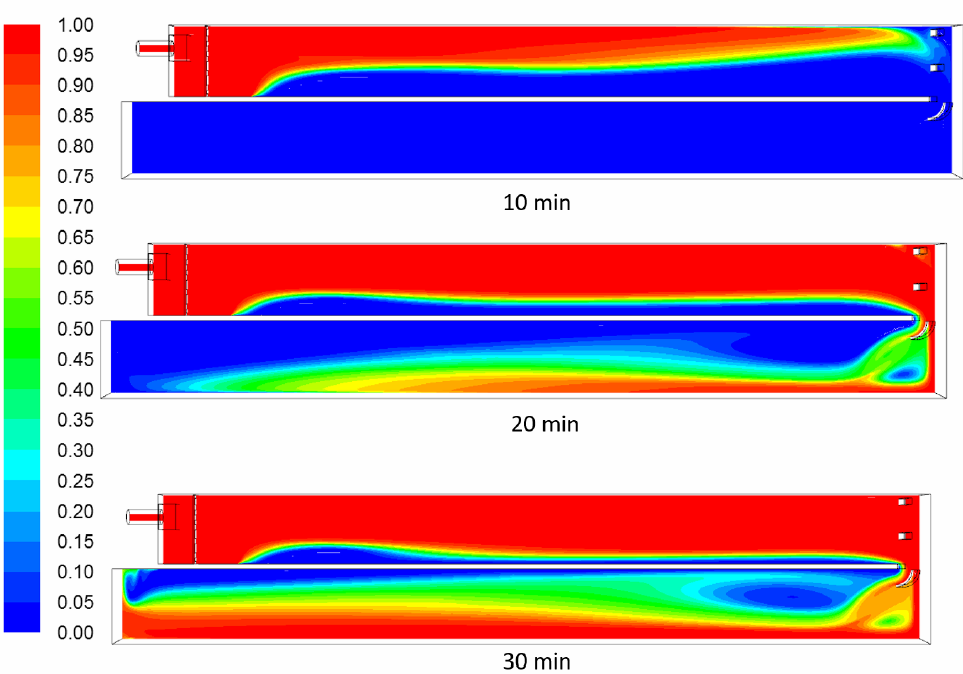

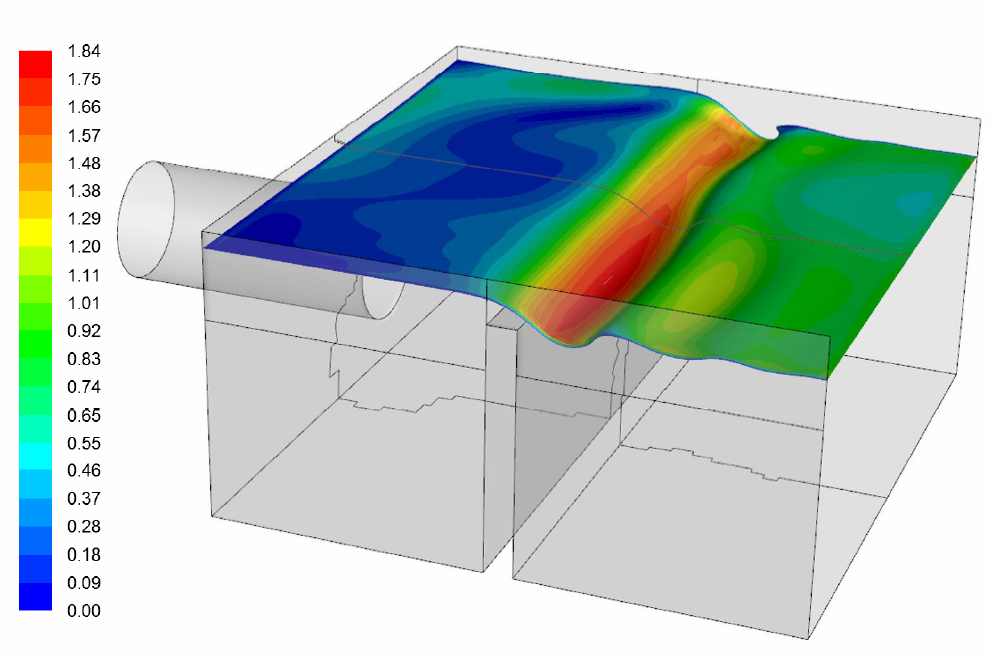

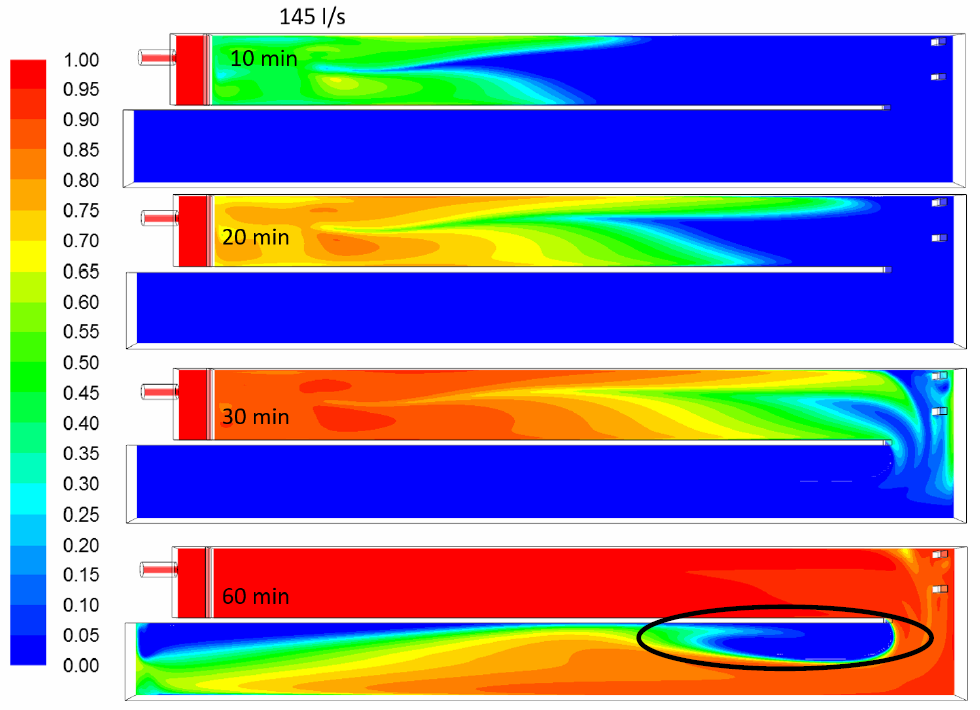

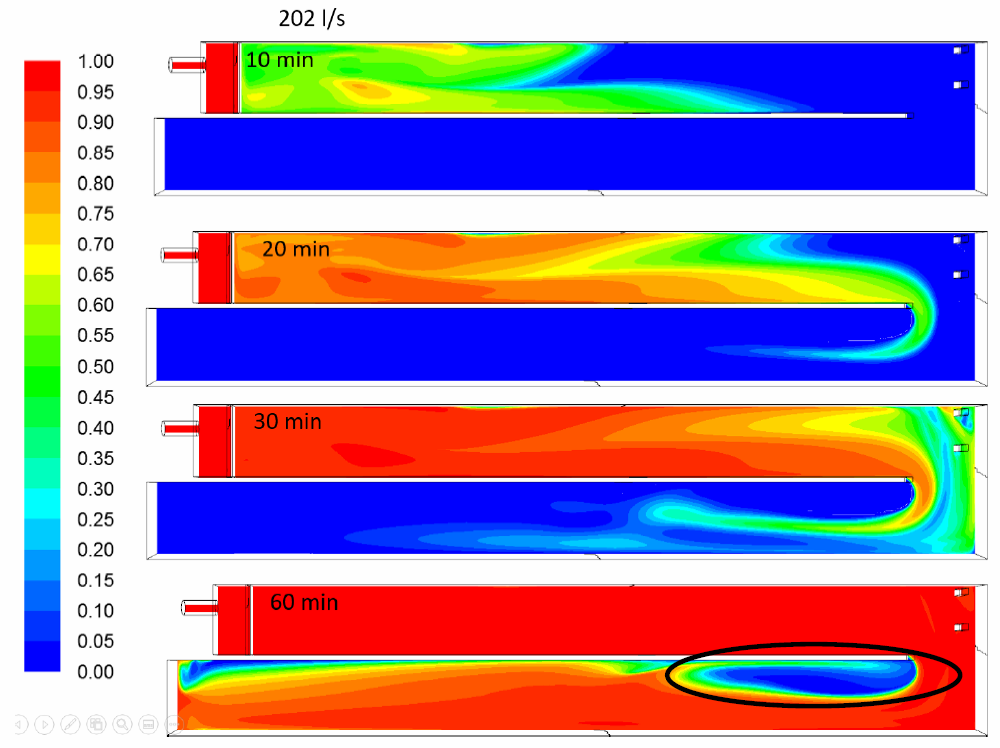

The tank was modelled simulating operation at low (290 l/s), medium (405 l/s), and high (521 l/s) flow rates with an average water level of 1.76 mOD. Results from the initial CFD study concluded that due to the geometry of the tank, several recirculation zones were evident. Given the position of the inlet is offset from the centreline caused a continual left hand flow bias, in conjunction with the constriction at the end of the tank which further initiated flow separation.

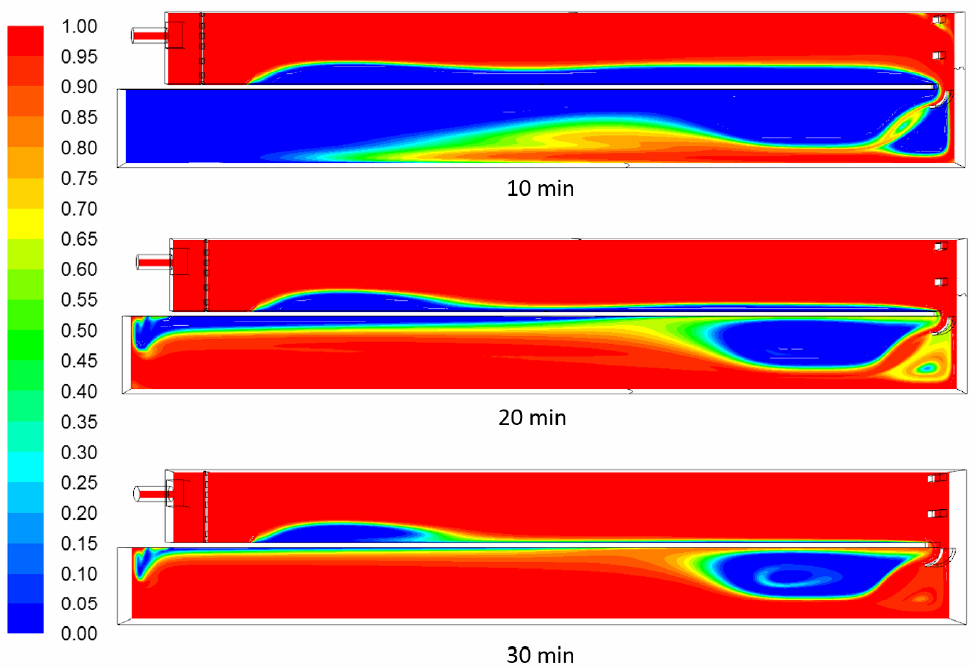

It was further considered that the steel baffle, distribution blocks, and a flow conditioning wall weren’t sufficient in providing adequate utilisation of the available volume which produced zones of stagnation, which are considered to be the cause of the issue onsite. Therefore the tank model geometry was modified with the removal of steel baffle and recurved wall, followed by increase in height of the weir local to the inlet with an increase in gap between the tank’s dividing and exterior walls to improve flow efficiency.

Following the modifications, results from the analysis demonstrated that the changes made provided a more satisfactory hydraulic environment within the tank as such this is considered that the onsite issues of stagnation and build-up of slime should be eradicated.