Yorkshire Water’s Hull Treatment Inlet Works

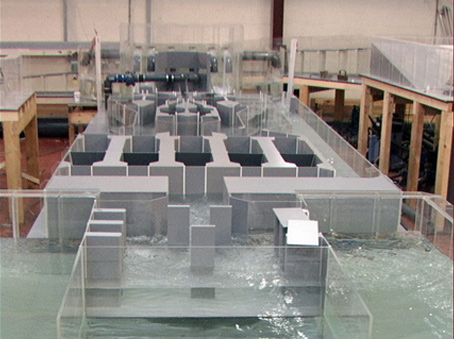

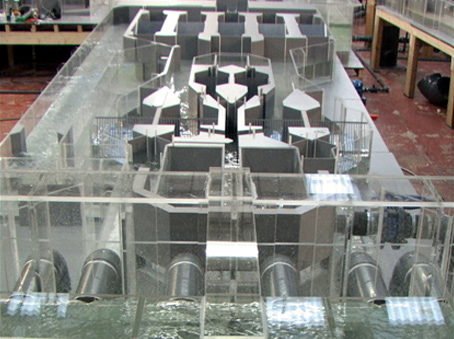

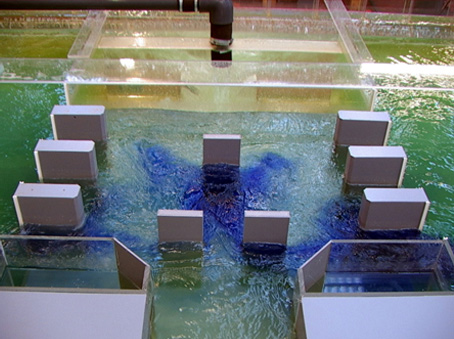

Client: M.J. Gleeson/MWHScale: 1/10th

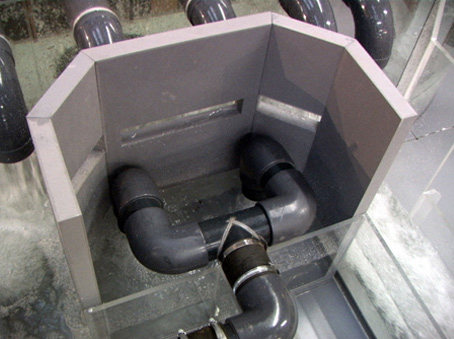

The existing Hull Waste Water Treatment Works inlet plant provides fine screening and grit and grease removal for flows discharging from a low level inlet pumping station. The station comprises four variable speed FFT pumps, each rated at 667 l/s, and 12 fixed speed storm pumps, each with a duty point flow of 1,660 l/s, providing a required total peak discharge capacity of 22 m3/s. Up to a maximum 2 m3/s are handled by the FFT arrangement and up to a maximum of 12 m3/s by the storm arrangement. The balance of 8 m3/s, discharges via two dual overflow weirs into a storm outfall pipe.

The arrangement comprised both an FFT and Storm flow stream. Flows up to FFT are contained within separate pumping and screening streams from storm flows. FFT flows up to 2.0 m3/s are discharged into a dedicated reception chamber and are passed through both dedicated coarse and fine screening facilities, prior to being discharged to a series of common spiral flow grit tanks.

Storm flows are delivered into the high level, crescent shaped storm reception channel from 12 fixed speed pumps, before the flow is directed into either or both (depending on inflow) of the two storm channels. Again, both storm and FFT flows will remain separate through the screening sections of the works. The maximum pumped inflow was determined as 20 m3/s. As the screening plant can handle flows of up to 12 m3/s, there is a potential for 8 m3/s of excess flow, which will be delivered over a dual overflow weir arrangement prior to being discharged to an outfall. Excess flows are backed up using modulating penstocks to ensure that the downstream works does not become inundated. Storm flows will be passed through a series of coarse and fine screen facilities, prior to entering the common grit and grease removal tanks. Both the FFT and Storm flow streams were equipped with dedicated by-pass channels, should any element of the coarse or fine screening plant be isolated for maintenance.

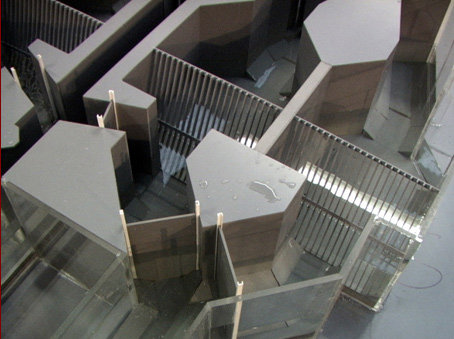

The model was constructed to a scale of 1/10th full size and comprised both the storm and FFT discharge chambers, storm and FFT coarse and fine screening facilities, in addition to the spiral flow grit tanks and all by-pass channels.

Initial testing demonstrated several areas of concern, including poor distribution of flow onto the various screens in both the FFT and storm channels, significant flow separation on entry to the SFGT’s, resulting in excessive velocity, poor spiral flow performance and a resulting increase in grit settlement track length. Several low velocity zones were highlighted that would have been subject to long term deposition and suitable infill benching was developed to eliminate these areas, whilst maintaining a hydraulically sound arrangement. Testing also looked at optimising the upstream storm control weirs to ensure that the maximum flow of 14,000 l/s (12,000 l/s storm plus 2,000 l/s FFT) could be passed through the works and down the by-pass without over topping the existing coping level, or prematurely spilling over the storm weirs to the outfall.

Testing demonstrated that the most onerous conditions were apparent during total station failure, when there will be a requirement to pass 14,000 l/s through the by-pass. While the flow was maintained beneath the coping level at all times, the storm overflow weirs spilled prematurely. There was therefore a requirement to re-assess and optimise the weir levels accordingly.

The model test optimised the arrangement to eliminate the adverse hydraulic conditions noted and further improvements were made by optimising the operating philosophy of the works. Since completion of the works, inclusive of the physical and operational changes implemented by Hydrotec, the inlet works has operated in accordance with the specification and there have been no reports of any problems with either the hydraulics or the operating philosophy