- SOUTH JEDDAH - AL KHUMRA SCREEN CHAMBER AND PUMPING STATION

- BRA 3494 – Sabesp Sao Lourenco, High Pressure Pumping Station

- FRANKLEY DE-ALK TRANSFER PUMPING STATION

- Deephams FTFT Pumping Station and Inlet Culvert

- Riverside Sewage Treatment Works - Regional Sump 1

- La Villette Pumping Station

- Bewsey Bridge Pumping Station

- Suez Thermal Power Station - Intake Pumping Station

- Norway Road Pumping Station

- Grimonpont RAS Pumping Station

- Nab's Head Storm Inlet Channel and Storm Pumping Station

Pumping Stations

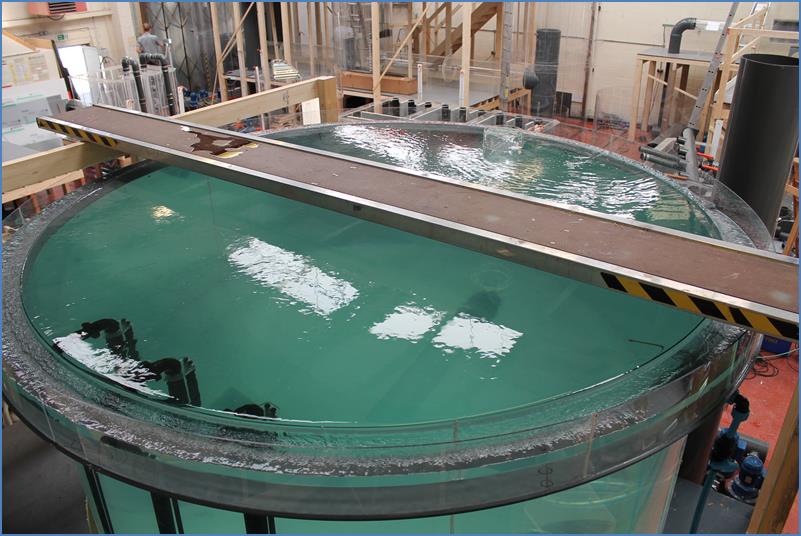

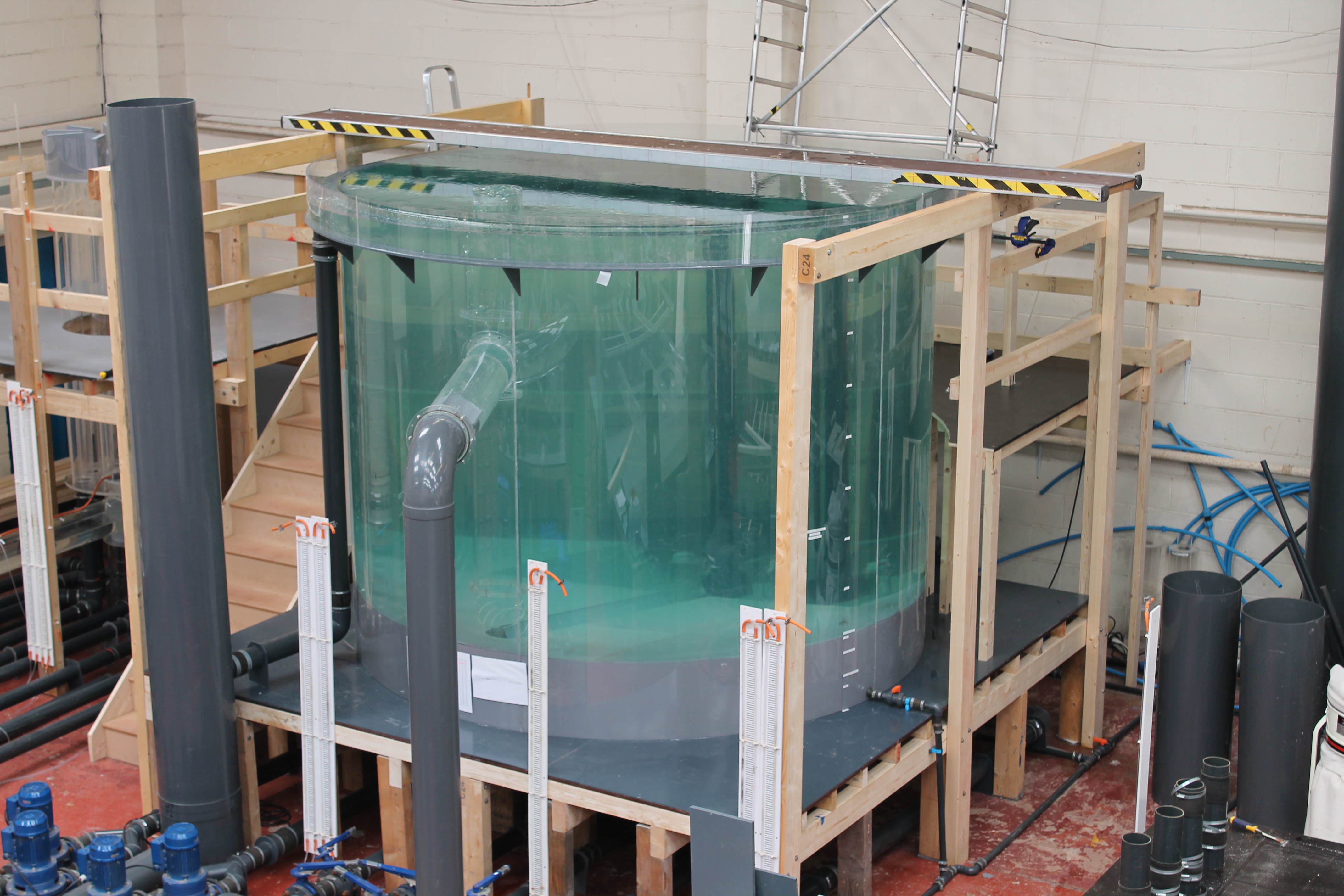

Norway Road Pumping Station

Client: MWHScale: 1/4th

The Portsmouth flood alleviation scheme is a £20 million investment by Southern Water to relieve the load of surface water on the sewerage system and to reduce the risk of flooding in parts of the Portsmouth and Southsea areas. The scheme will divert a significant amount of rainwater away from the combined sewers by discharging directly into the sea, as well as refurbishing some of the existing assets on the network. The Copnor Road with Norway Road Pumping Station forms part of this wider scheme.

The Norway Road Pumping Station will be operated as a transfer station; however, it will also provide significant storm storage of approximately 1000 m3. Pumped outflow from the Norway Road PS will be delivered to the surface water sewerage system in Quartremaine Road, which will deliver flow to the existing Great Salterns Surface Water lake. Flow will then be discharged out to sea, via the Great Salterns Surface Water Pumping Station and associated outfall.

Initial Testing

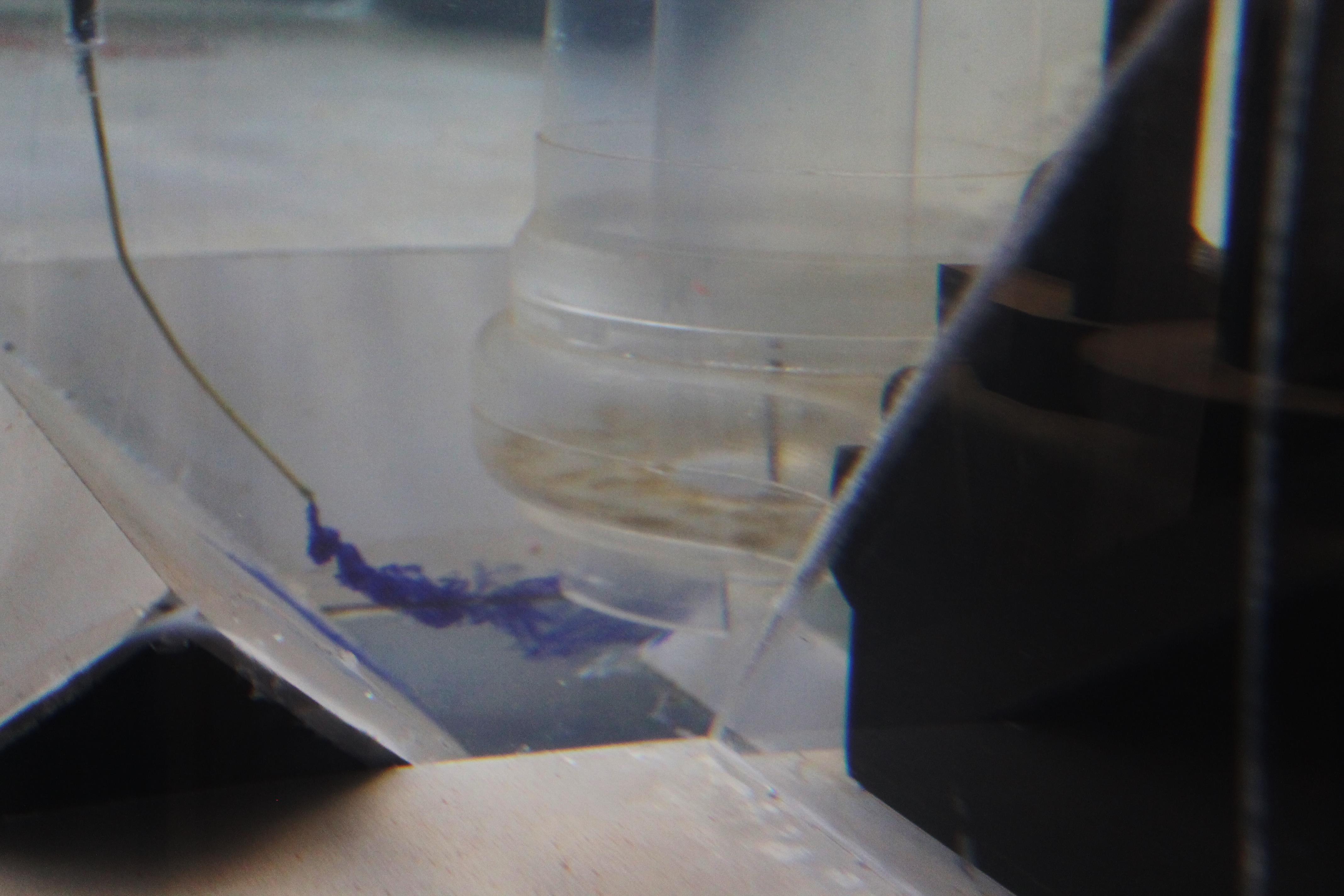

Initial testing demonstrated that when operating within the low level ‘low storm flow’ band, pump intake conditions were compromised by high turbulence, counter rotational flow patterns and the ingestion of a significant volume of entrained air bubbles; the latter being particularly evident on the central Pump P2. In addition, the formation of Type 2 to 3 submerged vortices was apparent connecting between the sump base and the intake, within the stall zone directly beneath all three operative pumps. The counter rotational flow patterns initiated swirling flow at the intake position and hence, values of time averaged pre-swirl rotation were considered to be excessive, peaking at around 10 degrees, which is notably above the recommended upper acceptance limit as determined in the ANSI standards, of 5.0 degrees bulk and 7.0 degrees intermittent peaks.

Development

The initially proposed arrangement was developed to provide a hydraulically sound environment for the pumps to operate in (i.e., elimination of swirling flows and vortices etc.) that also remained conducive to the maintained transport and clearance of settling solids. The extent of the modifications may be summarised as follows:-

- The adoption of an extended horizontal section of 900 mm diameter pipework on the downstream end of the inlet arrangement, located immediately downstream of the 90-degree elbow (to reduce rotational surface disturbance).

- The revision of the benching profile to provide an expansion channel towards the pump sump to improve lateral dispersion, reduce approach velocity and improve air transport towards the sump water surface. The channel comprised a sloped approach basin, to encourage maintained solids transport. The revised benching profile also formed a dedicated pump extraction trough, which reduced the adverse influence of high velocity approach flow, limited the influence of entrained air and provided a more even distribution to the pumps.

- The adoption of a cross baffle, located downstream of the discharge point, to intercept the incoming flow jet and provide improved lateral dispersion of the inflow; hence, reducing velocity and turbulence, while forcing air to re-surface away from the pumps.

- Infill benching local to the discharge point, to eliminate the potential deposition zone.

- The incorporation of 45-degree infill benching behind the pumps, to eliminate potential surface vortex formation and to deny deposition of settling solids on the pump plinth.

- The adoption of profiled inter-pump benching to limit cross flow within the pump extraction trough by forming individual extraction cells. The inter-pump benching also proved effective at eliminating the potential low velocity zone between pumps that may be subject to deposition under lower inflow periods and provided a more stable transition of flow into the pumps.

- The adoption of 45-degree profiled flow conditioning vanes, located directly beneath and along the centre-line of each pump, to break the initiating mechanism for submerged floor vortices and to pre-condition the suction draw into the pumps.

With the proposed modifications installed a hydraulically sound operating environment was achieved. There was no evidence of surface or submerged vorticity, the pumps were not subject to air ingestion and pre-swirl rotation was maintained within acceptable limits, generally below 1.0 degrees. In addition, acceptable solids transportation was maintained and while there may be areas of residual deposition (such as beneath non-operative pumps etc.), it was shown that over the course of several pumping cycles, the arrangement would be self-cleansing.

The proposed modifications remained effective across the full level range, inflow range and regardless of pump designation, number and combination

Final Testing

Following confirmation of the proposed modifications, the final testing programme was undertaken to confirm the suitability of the modified arrangement and to determine if acceptable pump intake conditions had been achieved, whilst maintaining a self-cleansing sump.

With the proposed modifications installed within the pumping station, the recommended operating levels adopted, inflows/pumped outflows maintained and the initially proposed control philosophy utilised, the final proposed arrangement of the Norway Road Pumping Station allowed for a satisfactory operating environment to be achieved, under both ‘normal’ and ‘storm’ periods of operation.